Introduction

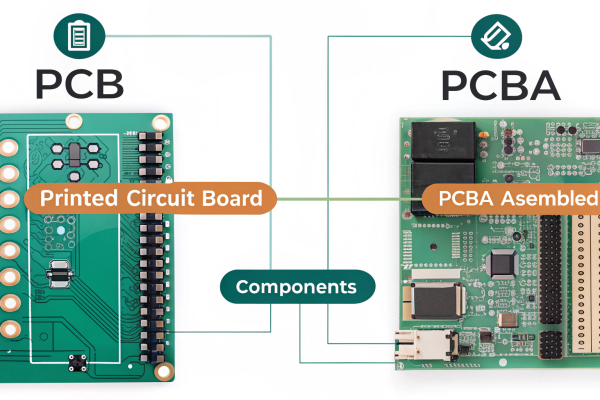

In the world of modern electronics, Printed Circuit Boards (PCBs) and Printed Circuit Board Assemblies (PCBAs) are the backbone of nearly every device we use. From smartphones to industrial machinery, these components play a critical role in ensuring functionality and reliability. But what exactly is the difference between a PCB and a PCBA? Why is this distinction important for engineers, manufacturers, and businesses?

This guide will break down the key differences between PCB and PCBA, explore their manufacturing processes, applications, and future trends, and help you understand why this knowledge is essential for making informed decisions in electronics design and production. Whether you’re a seasoned professional or new to the industry, this article will provide valuable insights to help you navigate the complexities of PCBs and PCBAs.

1. What is a PCB?

A Printed Circuit Board (PCB) is the foundation of any electronic device. It is a flat board made from non-conductive materials, typically fiberglass, with conductive pathways etched onto its surface using copper. These pathways, or traces, connect various electronic components like resistors, capacitors, and integrated circuits, enabling the device to function.

Structure and Functionality

- Non-Conductive Substrate: The base material, usually fiberglass, provides mechanical support.

- Copper Traces: These conductive pathways connect electronic components.

- Layers: PCBs can be single-sided, double-sided, or multi-layered, depending on the complexity of the circuit.

Types of PCBs

- Single-Sided PCBs: Conductive traces on one side only.

- Double-Sided PCBs: Traces on both sides, allowing for more complex designs.

- Multi-Layer PCBs: Multiple layers of substrate and copper traces, ideal for high-density circuits.

Applications

PCBs are used in a wide range of industries, including:

- Consumer Electronics: Smartphones, laptops, and home appliances.

- Automotive: Engine control units, sensors, and infotainment systems.

- Medical Devices: Heart monitors and imaging equipment.

For more details on PCB manufacturing, visit our PCB Manufacturing page.

2. What is a PCBA?

A Printed Circuit Board Assembly (PCBA) is the next step in the electronics manufacturing process. It refers to a PCB that has been fully assembled with electronic components, such as resistors, capacitors, and integrated circuits, soldered onto it. This assembly transforms the PCB into a functional unit capable of performing specific electronic tasks.

Importance of PCBA

- Functional Readiness: A PCBA is ready to be integrated into an electronic device.

- Versatility: PCBAs are used in everything from consumer electronics to industrial machinery.

Types of PCBAs

- Surface-Mount Technology (SMT): Allows for compact designs with smaller components.

- Through-Hole Technology (THT): Provides robust connections, ideal for high-stress applications.

Applications

- Computers: Processors, memory, and storage components.

- Telecommunications: Routers, phones, and signal transmission devices.

- Industrial Machinery: Automation systems and control panels.

For more information on PCB assembly, check out our PCB Assembly page.

3. Key Differences Between PCB and PCBA

Understanding the differences between PCB and PCBA is crucial for anyone involved in electronics design, manufacturing, or repair. Here’s a breakdown of the key distinctions:

Fundamental Distinctions

- PCB: A bare board with conductive pathways.

- PCBA: A PCB with components mounted and soldered onto it.

Functionality

- PCB: Serves as a platform for components.

- PCBA: Performs specific electronic functions.

Complexity

- PCB: Relatively simple, with only conductive traces.

- PCBA: More complex due to the addition of components.

Manufacturing Process

- PCB: Involves etching copper traces onto a substrate.

- PCBA: Involves component placement and soldering.

Cost Considerations

- PCB: Generally less expensive.

- PCBA: More costly due to added components and assembly processes.

Testing and Reliability

- PCB: Basic electrical testing.

- PCBA: Functional testing to ensure all components work correctly.

4. Advantages and Disadvantages of PCBs and PCBAs

Advantages of PCBs

- Compact Design: Reduces the size of electronic devices.

- Cost-Effective: Mass production is economically viable.

- Reliability: Minimizes errors compared to traditional wiring.

Disadvantages of PCBs

- Design Flexibility: Changes after fabrication can be costly.

- Environmental Vulnerability: Susceptible to damage from moisture and temperature fluctuations.

Advantages of PCBAs

- Functional Readiness: Ready for deployment in devices.

- Versatility: Used in a wide range of applications.

Disadvantages of PCBAs

- Higher Costs: Due to added components and assembly processes.

- Quality Control: Requires rigorous testing to ensure reliability.

5. Quality Control in PCB and PCBA Manufacturing

Quality control is critical in ensuring the reliability and performance of PCBs and PCBAs. Here’s how it’s done:

Design Verification

- Ensures the PCB layout meets specifications.

Material Inspection

- Checks the quality of substrates, copper foils, and other materials.

Process Control

- Monitors solder paste printing, component placement, and soldering.

Testing and Verification Methods

- Electronic Testing: Capacitance and resistance testing.

- Final Product Inspections: Ensures the assembled PCB meets design and functional specifications.

For more on quality control, visit our Quality Assurance page.

6. Common Applications of PCBs and PCBAs

Consumer Electronics

- Smartphones, tablets, and home appliances.

Automotive Applications

- Engine control units, sensors, and infotainment systems.

Aerospace and Defense

- Power supplies, communication equipment, and monitoring devices.

Medical Devices

- Heart monitors, imaging equipment, and diagnostic tools.

Industrial Machinery

- Automation systems and control panels.

7. Future Trends in PCB and PCBA Technology

Flexible and Wearable Electronics

- PCBs are evolving to support flexible and wearable devices.

3D Printing and AI

- Advancements in 3D printing and AI are impacting PCB and PCBA manufacturing.

Miniaturization and High-Speed Data Transfer

- Growing demand for smaller, faster, and more efficient PCBs and PCBAs.

Conclusion

In summary, the difference between PCB and PCBA lies in their functionality and complexity. A PCB is a bare board with conductive pathways, while a PCBA is a fully assembled board with components ready to perform specific tasks. Understanding these differences is crucial for anyone involved in electronics design, manufacturing, or repair.

For businesses looking to stay ahead in the electronics industry, partnering with a reliable PCB and PCBA manufacturer is essential. At MYRPD PCBA, we specialize in high-quality PCB manufacturing and assembly services tailored to your needs. Contact us today to learn more about how we can help you achieve your electronic design goals.