What is the Ultimate Guide to PCBA Assembly Steps, Files, and Cost?

Manufacturing electronics is hard. You worry about defects and high costs. I see many projects fail because of poor planning. You need a clear path

Manufacturing electronics is hard. You worry about defects and high costs. I see many projects fail because of poor planning. You need a clear path

Ensure flawless signal integrity in high-speed PCB designs with MYRPDPCBA’s expert strategies: impedance control, low-loss materials (Rogers 4350B), and simulation-driven validation. Reduce respins by 40% and achieve 25+ Gbps compliance. Explore our bulk PCB solutions.

The Role of PCB in IoT Devices: Key Design Challenges and Solutions

PCBs are essential for IoT devices, enabling connectivity and performance. Key challenges include miniaturization, power management, and security. Solutions like advanced materials, DFM, and automation ensure reliable, high-performance designs. For buyers, partnering with experts like MYRPD PCBA is crucial for success.

How to Perform Effective Quality Control in PCBA Assembly: Learn the essential stages, advanced inspection technologies, and best practices for ensuring defect-free PCB assembly. From pre-production checks to post-assembly testing, discover how to optimize your quality control process and meet industry standards like ISO 9001 and IPC-A-610. Ensure reliability and customer satisfaction with MYRPDPCBA’s expert PCBA services.

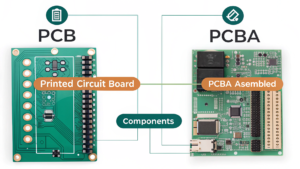

What is the Difference Between PCB and PCBA?

A PCB (Printed Circuit Board) is a bare board with conductive pathways, while a PCBA (Printed Circuit Board Assembly) is a fully assembled board with components soldered onto it. PCBs provide the foundation for electronic circuits, whereas PCBAs are functional units ready for deployment in devices. Understanding this distinction is crucial for electronics design, manufacturing, and quality control. Learn more about PCB and PCBA applications, manufacturing processes, and future trends in this comprehensive guide.

Discover the top 5 trends shaping PCB manufacturing in 2025: automation, miniaturization, sustainability, advanced materials, and IoT/5G integration. Learn how these innovations can transform your business. Explore now.

Introduction With the rapid development of artificial intelligence technology, AI glasses have emerged as a new type of smart wearable device, gradually becoming a focal

Choosing the right PCB supplier can not only improve production efficiency, but also enhance product competitiveness. Please don’t hesitate, take action now!

Resistors are the basic components in the circuit. After testing the conductivity of various materials and discovering the existence of electric currents

There are many types of resistors. The commonly used resistors include carbon film resistors, cement resistors, metal film resistors, and wire-wound resistors; special resistors include varistors, thermistors, and photoresistors.