Introduction

The Internet of Things (IoT) is revolutionizing industries, from smart homes to industrial automation and healthcare. At the heart of every IoT device lies a Printed Circuit Board (PCB), the unsung hero that enables functionality, connectivity, and performance. However, designing PCBs for IoT devices comes with unique challenges, such as miniaturization, power management, security, and manufacturing complexity.

This article explores the critical role of PCBs in IoT devices, delves into the key design challenges, and provides actionable solutions to help buyers and bulk purchasers make informed decisions. Whether you’re sourcing PCBs for smart home systems, wearables, or industrial IoT applications, this guide will equip you with the knowledge to overcome design hurdles and optimize performance.

1. The Role of PCBs in IoT Devices

1.1 Understanding PCB Functionality in IoT

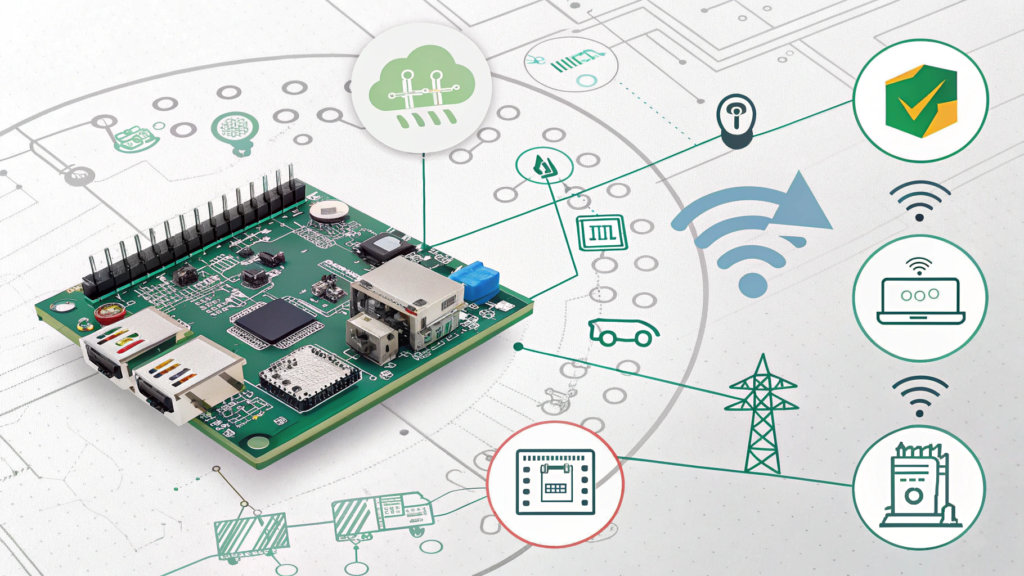

PCBs are the backbone of IoT devices, integrating essential components like sensors, processors, and communication modules. They enable seamless data exchange and connectivity, ensuring devices interact efficiently within IoT ecosystems. For example, in a smart home system, PCBs allow thermostats, smart locks, and lighting systems to communicate and function cohesively.

1.2 Size and Form Factor Considerations

IoT devices demand compact designs without compromising performance. Miniaturization and high-density interconnects are key techniques used to optimize space. Additionally, rigid-flex PCBs—combining rigid and flexible substrates—are ideal for wearables and medical devices, offering improved connectivity and reduced bulk.

1.3 Multi-Layered Designs for Enhanced Performance

Multi-layered PCBs are increasingly used in IoT applications to manage signal integrity and reduce electromagnetic interference (EMI). These designs support advanced functionalities like smart sensors and industrial automation, ensuring reliable operation in demanding environments.

2. Key Design Challenges in IoT PCB Design

2.1 Miniaturization

As IoT devices shrink, PCB designers face the challenge of fitting more components into smaller spaces. Higher component density and tighter spacing requirements demand innovative solutions to maintain performance and reliability.

2.2 Power Management and Energy Efficiency

IoT devices often operate on limited power sources, making energy efficiency a top priority. Designers must balance low power consumption with high performance, especially for battery-operated or remote applications.

2.3 Security Concerns

IoT devices are vulnerable to cyber threats, including hacking, data breaches, and unauthorized access. Weak encryption, insufficient testing, and default passwords exacerbate these risks, making robust security measures essential.

2.4 Privacy Concerns

The collection and storage of user data by IoT devices raise significant privacy concerns. Designers must implement strong security protocols and ensure compliance with privacy regulations to protect user information.

2.5 Manufacturing Complexity

Multi-layer PCBs and complex designs increase production costs and challenges. Balancing performance, cost, and manufacturability is critical for successful IoT PCB production.

2.6 Form Factor and Product Integration

IoT devices come in various shapes and sizes, from wearables to industrial sensors. PCB designs must accommodate unique form factors and integrate seamlessly with non-traditional materials.

3. Solutions to IoT PCB Design Challenges

3.1 Utilizing Advanced Materials

Advanced materials like ceramic and metal-core substrates offer superior thermal and electrical properties, making them ideal for high-performance IoT applications. Additionally, eco-friendly materials align with sustainability goals, appealing to environmentally conscious buyers.

3.2 Design for Manufacturing (DFM)

Incorporating DFM principles ensures efficient production by minimizing complexity and adhering to standard design rules. This approach reduces costs, improves yield, and avoids manufacturing defects.

3.3 Simulation and Prototyping

Simulation tools allow designers to test PCB performance under various conditions, reducing the need for multiple prototypes. This iterative process enhances reliability and durability in the final product.

3.4 Collaboration and Communication

Effective collaboration between designers, manufacturers, and cross-disciplinary teams is essential for overcoming design challenges. Regular design reviews and clear communication ensure all stakeholders are aligned.

3.5 Emphasizing Security

Integrating encryption, secure authentication, and OTA updates into PCB designs safeguards IoT devices against cyber threats. These measures are critical for protecting user data and maintaining device integrity.

3.6 Embracing Automation and AI

Automation in PCB manufacturing improves efficiency and consistency, while AI-driven design tools optimize component placement and routing. These technologies streamline production and minimize errors.

4. Case Studies: PCB Design in IoT Applications

4.1 Smart Home Systems

PCBs enable seamless connectivity in smart home devices like thermostats and smart locks, enhancing user experience and functionality.

4.2 Industrial Internet of Things (IIoT)

Multi-layered and flexible PCBs are essential for industrial automation, ensuring reliability and performance in harsh environments.

4.3 Wearable Technology

Compact and flexible PCBs are used in fitness trackers and smartwatches, delivering high performance without compromising comfort.

4.4 Biomedical Devices

Stretchable and flexible PCBs are revolutionizing healthcare, enabling continuous monitoring through lightweight and adaptable designs.

5. Future Trends in IoT PCB Design

5.1 Miniaturization and Integration

The trend toward smaller form factors continues, with system-in-package (SiP) technology enabling complex functionalities in compact designs.

5.2 Sustainable and Eco-Friendly Materials

The use of renewable and recycled materials in PCB manufacturing is gaining traction, aligning with sustainability goals and industry regulations.

5.3 Enhanced Connectivity Solutions

Multi-protocol support (Bluetooth, Wi-Fi, Zigbee) ensures seamless communication across IoT ecosystems, improving interoperability and user experience.

5.4 Advanced Power Management Techniques

Emerging techniques like energy harvesting and sleep modes extend battery life and improve energy efficiency, crucial for remote IoT applications.

5.5 Enhanced Security Features

Future PCB designs will prioritize secure boot processes, data encryption, and secure communication protocols to combat evolving cyber threats.

Conclusion

PCBs are the foundation of IoT devices, enabling connectivity, functionality, and performance. However, designing PCBs for IoT applications presents unique challenges, from miniaturization and power management to security and manufacturing complexity. By leveraging advanced materials, DFM principles, and automation, designers can overcome these hurdles and create high-performance, reliable IoT devices.

As the IoT landscape evolves, staying ahead of trends like sustainability, enhanced connectivity, and advanced security will be critical for success. For B2B buyers and bulk purchasers, partnering with a trusted PCB manufacturer like MYRPD PCBA ensures access to cutting-edge solutions tailored to your needs.

Ready to elevate your IoT projects? Explore our PCB manufacturing and PCB assembly services today, or visit our blog for more insights into the latest industry trends.