Introduction

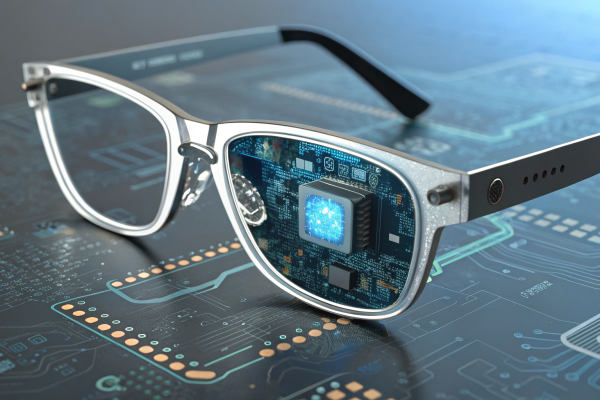

With the rapid development of artificial intelligence technology, AI glasses have emerged as a new type of smart wearable device, gradually becoming a focal point in the market. These devices not only provide users with augmented reality (AR) experiences but also show immense potential in various fields such as healthcare, education, and entertainment. This article will delve into the core components of AI glasses and the key points of PCB (Printed Circuit Board) manufacturing, helping you better understand this cutting-edge technology.

1.Understanding the Core Components of AI Glasses

AI glasses are primarily composed of the following core components:

- Display Module: Typically utilizing OLED or LCD screens, this module provides the interface for user interaction with the device. OLED screens are favored for their high contrast and wide viewing angles, allowing for more vivid image presentation.

- Processor: AI glasses are generally equipped with dedicated AI chips for real-time data processing and image recognition, supporting complex algorithms and multitasking.

- Sensors: These include cameras, microphones, and motion sensors responsible for capturing information from the surrounding environment to enhance the augmented reality experience.

- Communication Module: Modules such as Bluetooth and Wi-Fi enable wireless connections with other devices, supporting data transmission and remote control.

- Battery: High energy density batteries ensure the longevity of AI glasses, meeting users’ needs for extended usage.

2.The Role of PCBs in AI Glasses Functionality

PCBs serve as the “nervous system” of AI glasses, connecting all electronic components and ensuring they work efficiently together. The design and manufacturing of PCBs directly impact the performance, stability, and reliability of the devices.

Industry Statistics:

| Metric | Value |

| Market Size (2024) | Approximately $198 billion |

| Compound Annual Growth Rate (CAGR) | Approximately 43.8% |

This indicates the immense market potential for AI glasses, where high-quality PCB manufacturing is fundamental to realizing this potential.

3.Key Manufacturing Technologies for PCBs

Modern PCB manufacturing technologies continue to advance, especially in the application of AI glasses. The following technologies are particularly important:

- Multilayer Design: AI glasses often use PCBs with eight layers or more to accommodate a greater number of components and increase integration.

- Blind/Buried Hole Technology: This technology optimizes PCB space utilization and reduces interference between circuits.

- High-Density Interconnect (HDI): HDI technology enhances signal integrity and lowers manufacturing costs, catering to the demands of complex circuits.

4.AI Innovations in PCB Design and Production

AI is revolutionizing the ways in which PCB design and production are conducted:

- Accelerated Circuit Design: AI algorithms can rapidly generate circuit designs, improving design efficiency.

- Optimized Manufacturing Processes: Machine learning analyzes production data to help manufacturers identify potential issues, thereby enhancing quality control and reducing defect rates by up to 90%.

5.Challenges in PCB Manufacturing for AI Glasses

Despite continuous advancements in PCB manufacturing technology, manufacturers still face multiple challenges when producing PCBs for AI glasses:

| Challenge Area | Specific Issues | Solution Strategies | Expected Outcomes |

| Miniaturization | Component size reduction | Precision manufacturing processes | Maintain performance and reliability |

| High Yield Rates | Defects in complex designs | Advanced quality control methods | Improve production qualification rates |

| Environmental Adaptability | Stability across different environments | Enhanced material and design resilience | Ensure product reliability |

6.Future Trends in AI Glasses and PCB Technology

In the future, the development of AI glasses and PCB technology will exhibit the following trends:

- Enhanced AI Integration: The design process will increasingly incorporate artificial intelligence to improve efficiency and quality.

- Better User Experience: Improvements in sensor and interface design will continually enhance user experience.

- Innovative Power Management: New PCB designs will achieve more efficient power management, extending device battery life.

7. Successful Case Studies: Real-World Applications of AI Glasses

In this section, we will analyze successful case studies from several well-known companies to showcase how they effectively integrated PCB technology to enhance the performance and market competitiveness of their AI glasses.

Case Study 1: Google Glass

Company Background: Google Glass is a smart eyewear product launched by Google, aimed at providing users with augmented reality experiences. It is equipped with a camera, microphone, and display screen, enabling notifications, photo capture, and voice control.

PCB Technology Application:

- Multilayer PCB Design: Google Glass employs multilayer PCB designs to accommodate complex electronic components while maintaining a lightweight and aesthetically pleasing device.

- High-Density Interconnect (HDI): Through HDI technology, the PCB of Google Glass achieves higher signal integrity in a limited space, reducing signal interference and enhancing overall performance.

Results:

- Google Glass successfully achieved a compact design, giving the product a strong competitive edge in the market. Despite initial challenges, its innovative PCB design laid the groundwork for subsequent product iterations.

Case Study 2: Vuzix Blade

Company Background: Vuzix Blade is a smart glass designed for the enterprise market, offering real-time information display and voice control features, widely applied in logistics, healthcare, and manufacturing.

PCB Technology Application:

- High-Density Interconnect (HDI) and Multilayer Design: The PCB design of Vuzix Blade employs HDI and multilayer structures, allowing the device to integrate more features within a compact space.

- AI Quality Inspection: During production, Vuzix utilizes AI technology for quality inspection, ensuring each PCB meets quality standards and reducing production defects.

Results:

Vuzix Blade has received positive feedback in the market, especially among enterprise users, due to its efficient performance and stable quality, making it a leader in the smart glasses field.

Conclusion

The above case studies illustrate how several well-known companies successfully launched competitive AI glasses products through advanced PCB design and manufacturing technologies. The application of these technologies not only enhances product performance but also improves user experience, allowing businesses to gain valuable market share in a rapidly evolving landscape. With continuous technological advancements, more innovative AI glasses products are expected to emerge, further driving industry growth.

If you have any needs regarding PCB manufacturing or PCBA assembly, feel free to visit our PCB Manufacturing and PCB Assembly pages, or learn more through our Quality Control page. We are dedicated to providing you with professional services and support.